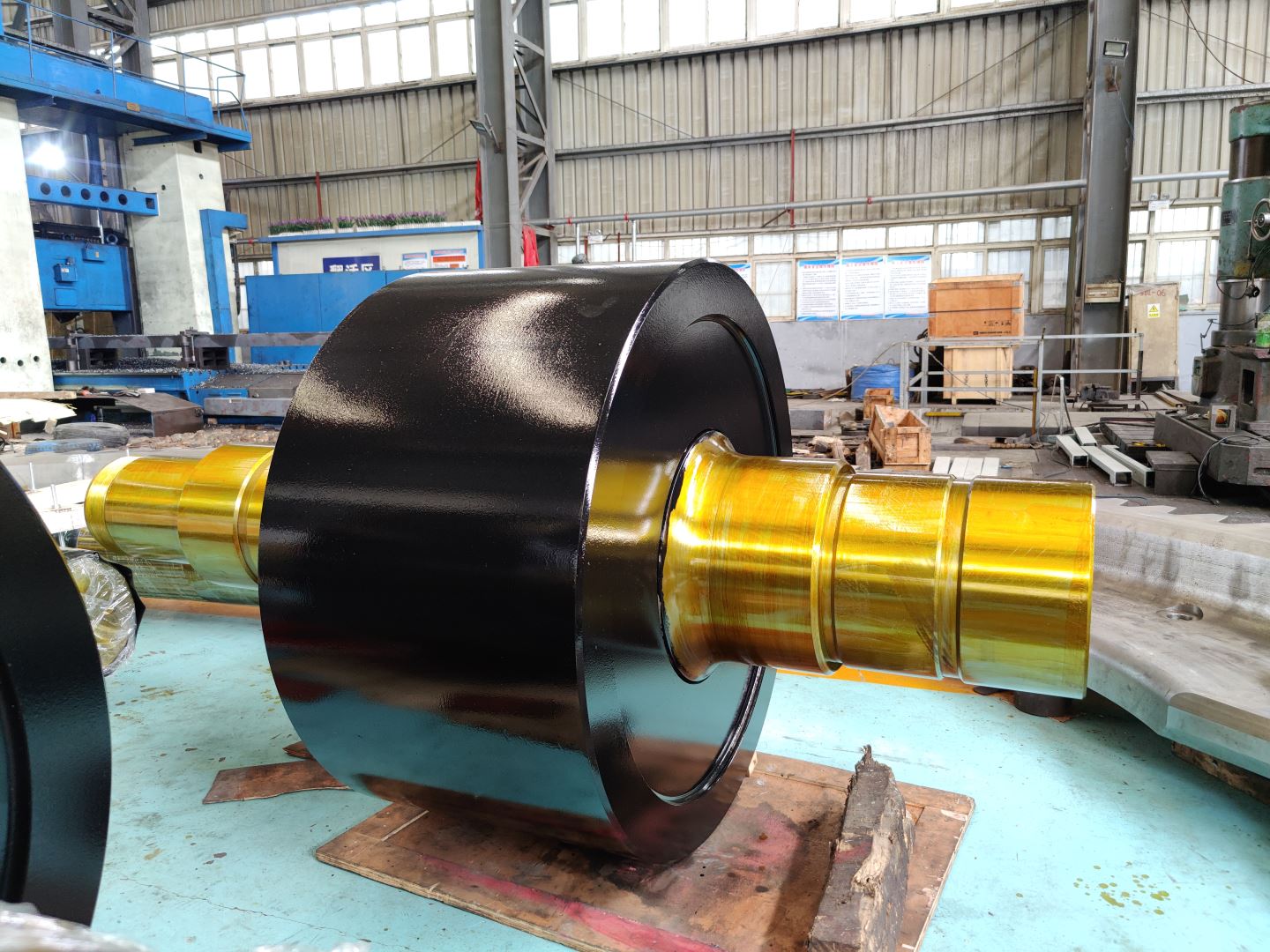

Our large ring gear is mainly used for large cement plant equipment.Such as Rotary kiln,Ball Mill,Dryer,etc.Also we can produce other big forging or casting gear ring for steel plant,Dragline excavator.

The can be a whole ring gear or segment gear wheel in half,four segments.eight segments.

Technology Process

Material is the skeleton for one machinery, while production design is the thought, CNC machining is the essence and heat treatment is the soul.

Electric Arc Furnace

It is easier and accuracy to control the inner temperature of furnace, so it can improve the purity of steel.

It can control the quality of steel from the material.

We can casting 1500-30000 kgs per piece.

Rough lathe machining of large ring gear is 2000-13000 MM. Our largest lathe diameter is 15 meters.

All our blank will do 100% Ultrasonic Flaw Detection

100% ultrasonic flaw detection of OEM custom large ring gear

Coarse hobbing of the OEM custom large ring gear

The Module of the large diameter ring gear is 8-55.

Magnetic powder inspection for the OEM custom large ring gear

Quenching & Tempering of OEM custom large ring gear

Coarse hobbing before the QT, which can make the good properties of the teeth.

Finished Hobbing for OEM custom large ring gear

The Maximum precision grade is 8, the grinding precision grade is 6.

Strictly quality inspection system can produce high quality products. Our quality certification system is ISO 9001:2015.

For each order,we can provide report for material chemical components testing,UT testing,hardness,mechanical property testing(impact testing,yield strength testing,tensile strength testing),size inspection,etc.

In order to avoid the finish products rusted and damaged during the transportation ,we will design the right packing according to the shape,size and usage of the products.

We can provide technical support on new material,heat treatment and new manufacture process according customer’s working condition in order to improve lifespan of machinery parts.

We have got a lot of patents on the spare parts of mill,cement rotary kiln,dragline excavator,rotor shafts.

Our products have been exported to abroad for more than 20 years and 43 countries,such as

America,Australia,Russia,Pakistan,Thailand,Indian,Morocco,Romania,Spain,etc.